CNC (Computer Numerical Control) machining has revolutionized manufacturing, allowing for highly precise and efficient production of complex parts. One of the key factors influencing the quality, cost, and functionality of CNC-machined parts is the material used. Different materials have distinct properties that make them suitable for various applications. In this post, we’ll explore the most commonly used materials in CNC machining and their unique characteristics. Also, read information about CNC machining Nashua NH.

1. Aluminum

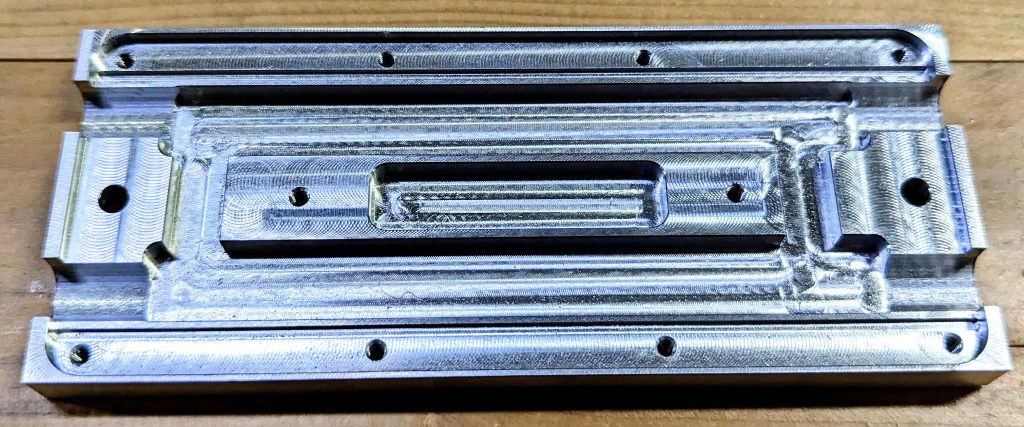

Aluminum is one of the most popular materials used in CNC machining due to its excellent combination of lightweight, strength, and corrosion resistance. It’s ideal for industries that require high strength-to-weight ratios, such as aerospace, automotive, and electronics.

- Advantages: Aluminum is easy to machine, versatile, and can be anodized for added protection against corrosion. It also has good thermal and electrical conductivity, making it useful for heat exchangers and electrical components.

- Common Uses: Aircraft components, automotive parts, electrical housings, and consumer electronics.

2. Steel

Steel is another commonly used material in CNC machining, prized for its toughness, durability, and versatility. There are various types of steel, including carbon steel, stainless steel, and alloy steel, each with its specific properties.

- Advantages: Steel offers a high strength-to-weight ratio and can be heat-treated to enhance its hardness and wear resistance. Stainless steel, in particular, is corrosion-resistant, making it ideal for medical devices and food processing applications.

- Common Uses: Tools, machinery parts, automotive components, medical implants, and kitchen appliances.

3. Titanium

Titanium is a high-performance material often used in industries where strength, lightness, and resistance to corrosion are critical. It’s known for its strength-to-weight ratio, making it an ideal choice for aerospace and medical applications.

- Advantages: Titanium is resistant to corrosion, particularly in extreme environments like marine or high-temperature settings. It is also biocompatible, making it ideal for medical implants and surgical instruments.

- Common Uses: Aerospace components, medical implants, high-performance engines, and sports equipment.

4. Plastics

Plastics are widely used in CNC machining due to their versatility, lightweight nature, and ease of machining. Common types of plastic materials used in CNC machining include ABS (Acrylonitrile Butadiene Styrene), nylon, polycarbonate, and PVC.

- Advantages: Plastics are often less expensive to machine than metals and are ideal for creating prototypes or low-volume production runs. Many plastics offer high chemical resistance and can be molded into complex shapes with ease.

- Common Uses: Consumer products, automotive interior components, housings, and medical devices.

5. Copper and Brass

Copper and brass are non-ferrous metals that have excellent electrical conductivity, corrosion resistance, and machinability. Copper is commonly used for electrical components, while brass is valued for its strength and aesthetic appeal.

- Advantages: Both materials are relatively easy to machine and offer good corrosion resistance. Copper is known for its high thermal and electrical conductivity, while brass has superior strength and is used in decorative applications due to its golden appearance.

- Common Uses: Electrical connectors, plumbing fixtures, musical instruments, and decorative hardware.

6. Carbon Fiber

Carbon fiber is a high-performance composite material used for applications that demand lightweight yet strong materials. It’s made from carbon fibers embedded in a polymer matrix and is ideal for industries like aerospace, automotive, and sporting goods.

- Advantages: Carbon fiber is incredibly strong and lightweight, offering excellent fatigue resistance. It also has high stiffness and can be molded into complex shapes. While it can be expensive, its strength and weight advantages make it valuable for specialized applications.

- Common Uses: Aerospace components, high-performance sports equipment, automotive parts, and military applications.

7. Wood and Composites

While wood and composite materials are not as commonly used as metals and plastics in CNC machining, they still have significant applications in industries such as furniture manufacturing, woodworking, and the creation of custom signage.

- Advantages: Wood is relatively easy to machine and can be shaped into intricate designs. Composites such as MDF (Medium Density Fiberboard) are versatile and can be used for a variety of applications. Wood and composites are often chosen for their aesthetic appeal and environmental friendliness.

- Common Uses: Furniture, custom cabinetry, signage, and decorative parts.

8. Ceramics

Ceramics, such as alumina and zirconia, are materials that are highly resistant to wear, heat, and corrosion. Although they are more brittle than metals and plastics, ceramics are ideal for applications requiring extreme hardness and durability.

- Advantages: Ceramics have excellent thermal resistance and are electrically insulating. They are often used in industries that require precision components that can withstand high temperatures or abrasive environments.

- Common Uses: Aerospace components, electronic insulators, cutting tools, and medical devices.

Conclusion

The material chosen for CNC machining plays a crucial role in determining the performance and cost-effectiveness of a part. Aluminum, steel, titanium, plastics, copper, and composites all offer unique advantages that make them suited to specific applications. Understanding the properties of each material and their intended use will help manufacturers select the best option for their projects. As CNC machining technology continues to advance, the range of materials available will only increase, opening new possibilities for high-performance applications across various industries.